Many people ask “What is sublimation printing and why choose to sublimate vs. screen print” or “whats sublimation? Sublimation is the process of transferring dye to a fabric using heat. The images and graphics are printed on special paper placed on the garment and heat is applied, allowing the ink to become part of the fabric. This will leave you with a more breathable, soft-hand feel to the fabric. The best part is that the numbers, letters and graphics do not peel, wear off, or come out in the wash!

Sublimation is a great process that allows for vibrant, full color, all-over prints.

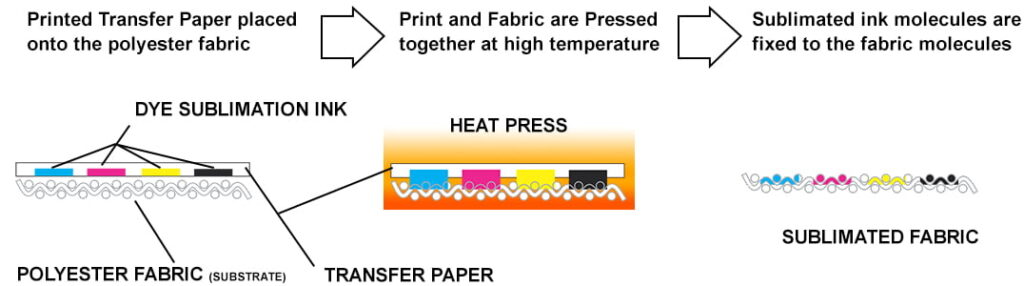

SUBLIMATION PRINTING DIAGRAM, PROCESS OF SUBLIMATION & THE DEFINITION OF SUBLIMATION

How do we define sublimation or define sublimated? Sublimation is a chemical process where a solid turns into a gas without going through a liquid stage. In this case an example is the ink that is printed on our transfer paper turns into a gas which then fuses into the fabric which becomes your sublimated sports product.

See below sublimation diagram as well as an explanation of the process of sublimation.

SUBLIMATION DIAGRAM SHOWING THE PROCESS OF HOW YOUR CUSTOM UNIFORMS ARE MADE.

STEP 1: SUBLIMATION DYES ARE LOADED ON THE PRINTER. STEP 2. YOUR CUSTOM UNIFORM DESIGN IS PRINTED ON A SPECIAL TRANSFER PAPER.

STEP 3: HEAT IS APPLIED TO TRANSFER YOUR DESIGN TO WHITE FABRIC. STEP 4 & 5. THE FABRIC WITH DESIGN IS CUT AND SEWN TOGETHER.

Subllimation dyes are loaded in the printer. The colors are usually in the CMYK color space.

Images are then printed onto the transfer paper. There are no limitations to colors and designs.

Heat is applied to transfer the ink to the fabric to undergo the sublimation process.

Ink is fused into the pores of the fabric and the garment panels are cut from the reels of the fabric.

The panels are sewn and pieced together and turned into an amazing sublimated sportswear product.

ADVANTAGES OF SUBLIMATION

Unlimited colors with no added cost.

Produces vibrant colors, making it perfect for photographic images.

Ability to create complex all-over print designs on the front and back of your sublimated uniforms.

You can’t feel the print at all, it gives the fabric a soft feel.

Sublimation print will not crack, peel, or fade.

Enhance your garment by adding a heat transfer such as, rhinestones, hot fix glitter or foil.

Sublimation printing never goes out of style. Because sublimated uniforms are custom made, there is no need to worry about a uniform being discontinued next season. It is also easy to reorder one from us in the future as we keep your design on file.

MORE IN-DEPTH: Sublimation Printing - What is it, and what can it do for you? How do we define the process of sublimation?

Some apparel decorators call it dye-sub, or dye sublimation printing, but no matter what you call it, sublimation printing is a versatile, digital printing method that opens up a world of opportunities to any consumer of decorated goods.

So, what is sublimation? Well, simply put, sublimation is a process by which sublimation dyes are printed onto a transfer medium with a specially prepared inkjet printer. Thereafter, those dyes are then transferred from the medium to an object or garment under the heat and pressure delivered by a commercial heat press. Sublimation only works on garments made of polyester, or on specialty objects made of polyester or given a polyester coating. When the heat and pressure are applied, the dye on the transfer medium sublimates, or becomes a gas, and is then absorbed into the polyester itself; the print is actually a part of the garment/coating. It doesn’t fade easily, wear, or have any texture or weight.

So, what does all of this mean to you, our customer? There are many benefits to the process:

Full color on small runs. Unlike screen printing, there is no need for separate screens, films, or a great deal of setup for sublimation. Though you may well need to have us refine your art, the process thereafter is straightforward, and on smaller orders may prove less expensive overall than screen printing.

Less need for minimum orders. We are more likely to be able to accommodate a smaller order or re-order when you sublimate, due to the reduced amount of setup needed to print your item.

Individual customization. Though art charges may apply for this level of customization, seeing as each garment is printed from it’s own transfer rather than en masse on the same set of screens, this method makes it much easier to add individual customization to each printed item.

Lighter hand. The nature of sublimation means that prints are never heavy or thick. The garment is unchanged by the process, save for the addition of your art.

Durability. There is no cracking or peeling in a sublimated print, they last as long as the garment.

Hamco Sports is the BEST at Full Sublimation Printing

Now you know why sublimation printing is the way to go for your team, league or organization. Here at Hamco Sports, our #1 focus is on sublimation uniforms and customized apparel.

Speed. After you place your order, you receive your order in 2-3 weeks.

Talented designers. Our design team knows exactly what you want and will create your dream uniforms. Our designs are free and included in all of our prices!

Professionally made. We use the most advanced technology and the highest quality fabrics to produce your customized apparel.

Look good, play good

FAQ – FREQUENTLY ASKED QUESTIONS

What products can sublimation printing be used on?

Sublimation is best used for white or light colored fabrics, usually polyester or a poly blend. Sublimation can also be used on polymer coated products such as coasters, mugs, mouse pads, phone cases, towels, basketball jerseys, glass etc.

Why is sublimation printing used?

Sublimation printing is the cheapest and most effective way to produce a full color print on polyester. Other processes like screenprinting, heat transfer or embroidery do not have the same effect and are more expensive, take longer or do not have the same desired effect. Sublimation is also an environmentally friendly printing alternative.

What does sublimation printing mean?

Sublimation printing, also known as dye sub or sublimation printing is a popular printing process for transferring images onto fabrics or materials. Sublimation excludes the liquid state and goes right from solid to a gas due to a chemical reaction. (kind of like dry ice.)

Is sublimation printing permanent?

Yes. Images and designs using the sublimation printing process yield beautiful and permanent colors that are embedded in to the substrate or fabric, rather than just printed on the surface.

Can sublimation printing be done on cotton?

No. You cannot do sublimation on 100% cotton. Sublimation must be done on 100% polyester for the best results. You can print on cotton shirts but it is not the same process as sublimation, but similar.

Is sublimation printing environmentally friendly?

Yes. Sublimation printing is the most environmentally friendly and sustainable process possible for sports apparel, garment printing and production. It produces no wastage and water is not required for the sublimation process.

Is sublimation printing good quality?

Sublimation printing produces a vibrant and high quality print on fabrics and materials. In comparison to other printing methods sublimation printing is the best process to produce a garment with endless design possibilities.

Does sublimation printing fade? Is sublimation printing durable?

Sublimation does not fade, peel off, come out in the wash or sun. Sublimation can print high quality photo prints or vector graphic designs which can be created and transferred to a polyester fabric or garment in a matter of minutes.

What temperature is used for sublimation printing?

The most common dyes used for sublimation printing activate during a range of 380 to 420 degrees Fahrenheit for optimal color.